Made from a series of bamboo arches spanning 19 metres, the Arc at the Green School in Bali is heralded as one of the most significant structures ever made from bamboo.

The Arc at the Green School in Bali was finished in 2021

Designed by architecture studio Ibuku and using approximately 12.4 tonnes of Dendrocalamus Asper, also known as Rough Bamboo or Giant Bamboo, the lightweight structure was finished in April 2021.

Such an eye-catching building shows the strength and versatility of bamboo. Add to that bamboo’s green credentials and it would seem like an excellent material to help the construction industry cut its carbon footprint.

Like trees, bamboo plants sequester carbon as they grow and can act as carbon sinks, storing more carbon than many tree species.

A plantation of bamboo can store 401 tonnes of carbon per hectare (per 2.5 acres). By contrast, a plantation of Chinese fir trees can store 237 tonnes of carbon per hectare, according to a report by the International Bamboo and Rattan Organisation (INBAR) and Delft University of Technology, in the Netherlands.

It is one of the fastest growing plants on the planet – some varieties grow as quickly as one metre per day.

Plus, bamboo is a grass, so when the stem is harvested it grows back, unlike most trees.

It has a long history of use in construction in Asia, but in Europe and the US it remains a niche building material.

In those markets, bamboo treated with heat and chemicals is becoming more common for flooring, kitchen tops and chopping boards, but is rarely used as a structural material.

Around 12 tonnes of bamboo went into making The Arc

According to Christopher Matthews, from London-based structural engineers Atelier One, part of the problem is a lack of familiarity.

“One of the biggest challenges was nobody really knows how to engineer in bamboo,” says Mr Matthews, who worked on the Bali School project.

“So we had to test it. We were there, loading it up with sandbags to actually prove how strong it was.”

Mr Matthews says demand for bamboo is increasing, with 30% of his company’s clients now using the material. “We’ve started developing more and more bamboo structures.”

He points to an entire school campus in New Mexico, and structures such as a yoga studio in Costa Rica, and a bridge and pavilion in the Philippines.

“In the countries that are using it, it’s extremely cheap and extremely abundant, and the workforce is skilled in using it. If we started using it in Europe, initially it’d be more expensive. But as it becomes more and more used, then there’s no reason why the cost can’t come down.”

He says the company is in early stage conversations to help build with bamboo in the UK soon.

BambooLogic has plantations in Portugal

It would help if bamboo was grown in Europe, but the larger species don’t grow well in chilly northern climates.

BambooLogic is hoping to change that – it is the first large-scale bamboo grower in Europe.

“For sure, it needs a lot of sun, some water as well,” says Jan Detavernier, a consultant at BambooLogic, which has bamboo plantations in Portugal.

“In the south, we have a lot of sun.” He says it has the potential to restore degraded soil. “Where we grow in the south of Portugal, the soil is very poor. Since the bamboo captures CO2 and puts it in the ground, it makes the earth much better.”

Mr Detavernier says his firm is working with partners that are developing new products for the European market.

The challenge, he says, is a lack of standardisation. “In Europe we are not used to working with bamboo as a material. There’s a lot of data in Asia, but there’s little data in Europe to work with.”

Dr Bhavna Sharma, assistant professor of architecture at the University of Southern California’s School of Architecture, and also a member of the taskforce developing international standards for bamboo construction materials, echoes this.

“It’s a challenge still to use bamboo in construction because it is still a non-conventional material,” she says.

“It’s just [about] increasing our body of knowledge, understanding how the material would perform in different service environments, which means if I’m building in Amsterdam, how will the building perform in that type of weather and climate versus if I’m building in Indonesia? That way we can move even further in terms of the types of buildings that we’re able to construct.”

Dr Sharma says that the first engineered bamboo testing standards from International Standards Organisation were published last summer. “That will support practitioners, designers and engineers in adopting the material into projects.”

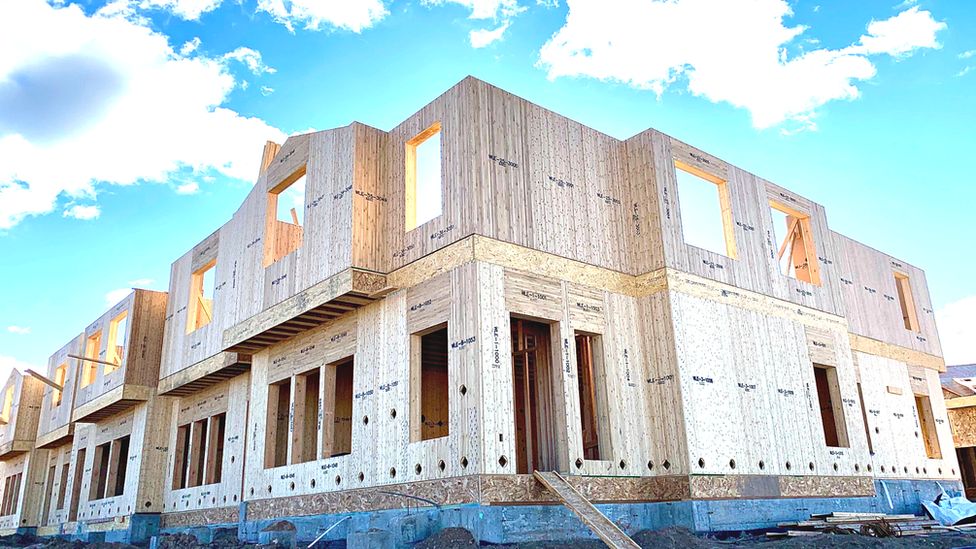

Here Bamcore panels are being used to build a residential building

In California, sustainable building materials company BamCore, established in 2019, offers a panelised framing system made up of either engineered bamboo and wood, or eucalyptus and wood. The panels are used to build buildings up to five storeys high for both commercial and residential buildings.

“Our customers originally started as single home buyers or architects that were looking to be more sustainable,” says Kate Chilton, chief sustainability officer at BamCore.

“But as we’ve started to grow, we have begun to bring on developers as customers.” She points to D.R. Horton, the largest homebuilder in the US, which she says, is in the process of piloting its bamboo product across several developments in the US.

There are more than 1,600 species of bamboo, and BamCore’s preferred is Dendrocalamus asper, more commonly known as Giant Clumping bamboo, which they import from South America and Asia. However, Ms Chilton says they are in talks with a bamboo plantation owner in Florida who has a Dendrocalamus asper trial ongoing.

Some are embracing the creative potential of bamboo. Event marketing agency, Natchlab, is creating a 650-sq m temple from recycled bamboo for the arts and music Boom Festival in Portugal next year.

“Open plan, well-ventilated, high structures are exactly what you need at a festival,” Mr Sibthorpe, Nachtlab’s creative director, said at the Green conference – part of the Amsterdam Dance Event.

“Bamboo can bend and mould a little bit. It’s a very malleable material.”

Suzanne Bearne (Source: bbc.com)